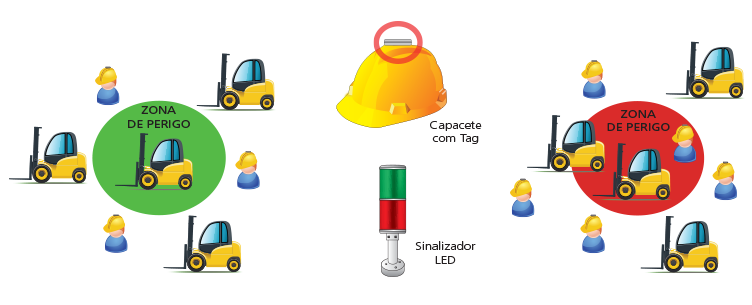

The main objective of the Auxiliary Proximity Detection System - SADP is to warn about the proximity of equipment and personnel around an equipment, or in this case, forklifts:

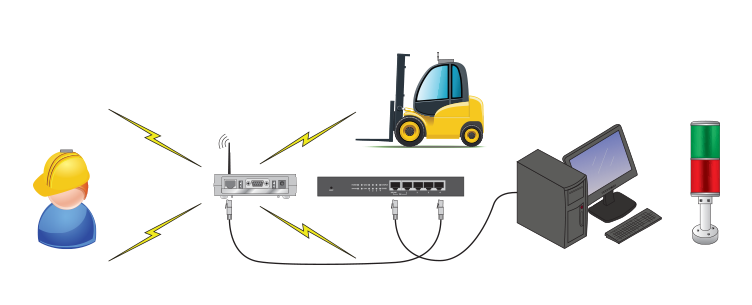

The RFID (Radio Frequency IDentification) technology used in the proposed System is of the Active type, which uses 2.4 GHz frequencies with the usage of batteries in the tags. The advantages of this technology are many, like its reading distance which can reach up to 100 m, and the extremely high reading speed. A big market differential is that the battery can be switched, so it's not needed to buy a replacement tag.

Sensor Module: The Sensor Module installed each forklift, on its central superior part. It is responsible for the detection of other modules in other forklifts or for people with helmet tags. It has an audiovisual indication to warn about the proximity of other forklift or person, through a column that lights green or red LEDs and a siren.

It has a panel with buttons for the forklift operator to warn when he is conducting it and to be ignored by the Sensor Module. When he leaves the conduction he warns it by the panel to be protected again by this forklift.

Web interface configuration.

Helmet TAG: The helmet tag is the device that people use to be detected by the system. It is attached by velcro and has two AA batteries that can be swapped when the system indicates low battery. The battery indication is done through:

Monitor Module: The Monitor Module will log all tags to detect if any of them is low on battery and warn user or responsible via email.

![]() Downloads:

Downloads: